How To Size A Hydraulic Pump And Motor

2 / 12 / 2021

How to Select a Hydraulic Pump and Motor

This article aims to provide guidance on building an effective hydraulic system, with communication on selecting a motor and compatible pump for the awarding.

When designing a hydraulic arrangement, choosing the right motor and pump is crucial for ensuring optimal performance. The goal behind edifice an efficient hydraulic solution is to select products that match the overall efficiency of the performance you are looking to achieve.

Motors and pumps are both cardinal components in any hydraulic system, and it's important that they work together in tandem. To attain this, there'southward a process that should exist followed when selecting a hydraulic motor and pump.

In this article, nosotros will ensure that you take a clear understanding of the differences betwixt a hydraulic pump and motor, the parts they play in a system, and how they should be paired.

So, what comes first? The motor or the pump?

The pattern and performance of a hydraulic system will change depending on the motor yous select, and so this should be the first step in the process. This is because the motor selection should be based on the system's load requirements get-go, before because a pump that will work to bulldoze the fluid ability into the motor.

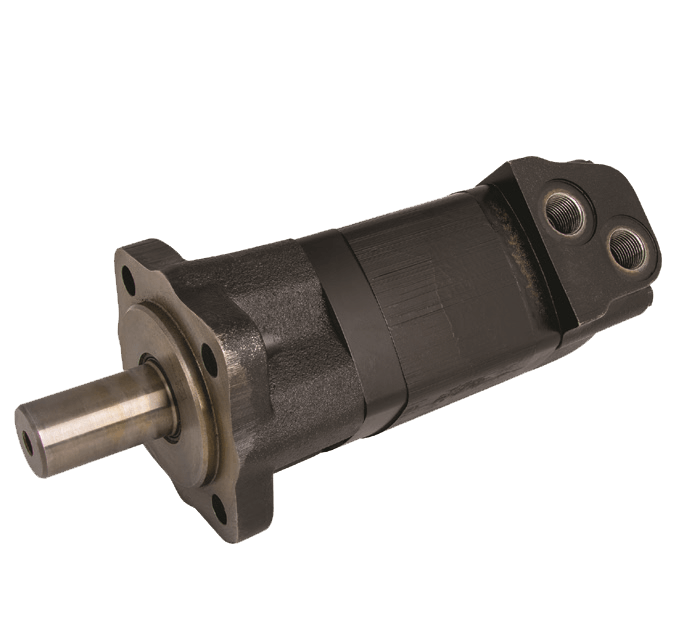

How to cull a hydraulic motor

Now that yous know the motor comes first in the process, how do y'all choose the right one for your application?

At that place are many different hydraulic motors available, all boasting varying operating specifications, features and performance profiles. This is the data that y'all volition use to make up one's mind which is the right fit for your hydraulic system – finding the one that best meets the operation expectations of your awarding.

Hydraulic motors produce a rotary actuation when pressure is applied from a fluid. This tin can either be a bidirectional or unidirectional actuation, depending on the design of the organization.

What to consider when choosing a motor

Operating specifications vary between motors, and they all offering different functioning indicators and capabilities which should be considered when looking to buy.

The main operating specifications of motors to look out for, are:

- Operating torque defines the torque that the motor is capable of delivering, i.due east. the corporeality of twisting activeness it tin can offer.

- Operating pressure is the pressure at which the fluid will be fed to the motor, which affects the motors' torque and power.

- Operating temperature dictates the temperature range of the fluid which the motor can handle. These will unremarkably be defined as minimum and maximum temperatures.

- Operating speed indicates the speed at which the motor rotates, in revolutions per minute (RPM).

- Power is dependent on the period and pressure of fluid beingness delivered to the motor, only each motor volition have dissimilar power capabilities.

- Displacement is used to rate motors and is measured in cubic inches per revolution (CIR), or cubic centimetres per revolution (CCR) which indicates the volume of fluid it takes to rotate the shaft once.

All of these specifications volition vary greatly between products, so it's important to match them up with the expectations of your system to cull the best hydraulic motor that will guarantee performance.

Types of hydraulic motor

In that location are many different types of hydraulic motor available, all designed to conform different systems and deliver varying performances. Typically, you lot will detect each motor placed into one of two classifications: high speed, low torque (HSLT) or low speed, high torque (LSHT).

The motor yous choose should have the capabilities and capacity to generate the output required for the application'due south needs. For best practice, consider choosing a motor that delivers college maximum ratings than required if the budget allows, to prevent it from existence overworked and extend its lifespan.

Gear motors

Gear motors are simple in pattern, consisting of a matched gear set enclosed in robust housing. The gears (internal or external) generate torque when the hydraulic fluid enters the motor.

They are typically classified equally LSHT motors, and offer a broad range of speeds and temperature ranges, with medium pressure capabilities. Small, compact and lightweight, gear motors are widely used in mobile hydraulics.

Vane motors

The large majority of vane motors are classified as HSLT units. They feature a vane that causes the output shaft to rotate once hydraulic fluid enters the motor, with medium pressure capabilities.

Used across a wide range of industrial and mobile applications, vane motors offer adept operating efficiencies and mostly produce less noise than other types of motors.

Piston motors

Piston motors are generally plant in 2 different types: axial and radial.

Centric piston motors generate output torque with the apply of an axially-mounted piston and are typically classified as HSLT units.

In radial piston motors, multiple pistons are mounted perpendicular to the shaft and tin can deliver high torques at low speeds.

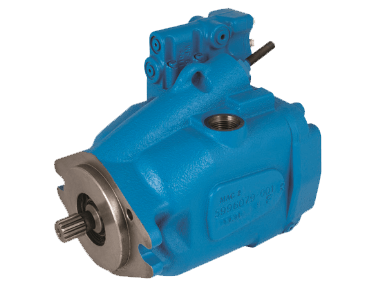

Choosing a hydraulic pump for your motor

Afterward selecting your hydraulic motor, you lot volition take a good agreement of the rating of the motor and therefore the ability output yous are looking for in a pump.

For best practice, it'due south recommended to choose a hydraulic pump with like ratings as the motor. To forbid the motor from beingness overloaded, the fitting of motor mounted force per unit area relief valves is brash.

{When designing the motor pump unit there should be at to the lowest degree 20% more power available than the system requires (fudge factor/condom cistron)}.

From gear pumps and vane pumps to piston pumps, at that place are many different options to consider. Whilst the motor called should assist in the requirements of your pump, other considerations also include:

- Hydraulic fluid viscosity – how thick is the hydraulic liquid that will exist pressurised by the pump? Pumps volition have a maximum kinematic viscosity rating which yous should attach to maximise efficiency.

- Flow rate – hydraulic pumps have a maximum flow rate depending on how much fluid they can move.

- Maximum operating pressure – this volition betoken how much force per unit area the pump tin can effectively handle without information technology causing harm to the component.

- Fixed displacement or variable deportation – choose the configuration that meets the demands of your awarding, whether you lot require the aforementioned corporeality of fluid moving (fixed), or changes to menses rate and outlet pressure (variable).

In a higher place all that, you volition need to correctly size your motor and pump to arrange the application. For this, many different mathematical formulas and equations should be factored into the process.

Designing a hydraulic system is no piece of cake task, and is certainly not something to go into with limited cognition of how the components work in conjunction with one another. For a hydraulic solution that meets all of your requirements, we highly recommend seeking the help of a professional.

Primary Fluid Power has over 40 years of hydraulic experience, with a team of technical experts ready to find the perfect solution for you. Whether y'all need some advice on which components you need or a bespoke build – nosotros tin help. Simply become in touch with us online or give usa a telephone call on 0151 632 9500.

How To Size A Hydraulic Pump And Motor,

Source: https://www.primaryfp.co.uk/how-to-select-a-hydraulic-pump-and-motor/

Posted by: youngiriplard1942.blogspot.com

0 Response to "How To Size A Hydraulic Pump And Motor"

Post a Comment